The Faux Fur Circular Knitting Machine integrates cutting-edge technology to enhance efficiency and fabric consistency:

NEEDLES

CYLINDERS

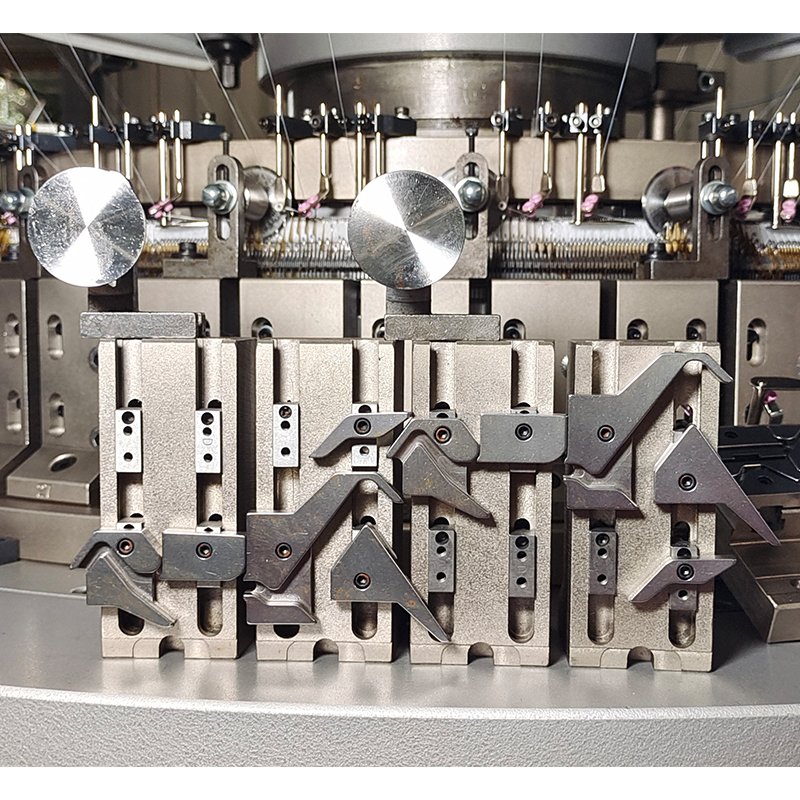

CAMS

SINKER

POSITIVE FEEDER

AUTO OILER

Send us a message if you have any questions or request a quote.

Our experts will give you a reply within 24 hoursand help you select the right valve you want.

Lorem lpsum dolor sit amet. consectetur adipiscing Ut elit tellus, luctus nec ullamcorper mattis,oulvinar dapibus leo.